PRODUCTS

Create Value With Full Auto Manufacturing

- HOME

- PRODUCTS

- TURNKEY SOLUTIONS

- VIDEOS

- ABOUT HENGTAI

- NEWS

- MESSAGE

- CONTACT US

One-step Silane Crosslink Extrusion Line

Application:

The one-step Silicohydride Crosslink Insulation Extrusion Line is designed for the insulation extrusion of cooper and aluminum conductors. It is suitable in the insulation extrusion for power cables range from 1kV to 10kV, also suitable for overhead conductors, plastic cables and etc. Applicable materials include PVC, PE and XLPE.

Technical Parameters:

Voltage | 1KV-10KV Crosslinking cable |

1KV-10KV Crosslinking aerialline | |

Conductor Material | Aluminum, Copper |

Up to IEC 228 Standard | |

Corss Sectional Area of Conductor | 10-630mm² |

Conductor Diameter | 4.0-40.0mm |

Cable Diameter | 9.5-42.0mm |

Weight of Cable | Max. 7.0kg/m |

Wall thickness | Inner shied:0.4-0.8mm |

Insulation: 0.8-3.5mm | |

Color Skin: 0.1-0.5mm | |

Line Speed Max. 80m/min | |

Capacity of Extrude 65/25D | PE: Max. 120kg/h |

120/30D | PE:Max.450kg/h |

Middle Voltage Cable | |

Inner Shied Material | Semi-conductive PE(Borealis), SIOPLAS(AEI) |

Insulation Material | PE,2100TN00,218W, 18D.. |

Liquid Silane | SILIX, SILMIX316,301 |

Carbon black master batch: silix-c401 | |

Low Voltage Cable | |

Insulation Material | PE, 2100TN00,218W, 18D... |

Liquid Silane | SILIX, SILMIX316,301 |

Carbon black master batch: SILIX-C401 | |

Color Skin | PE,PVC or SIOPLAS (AEI), Color Masterbatch |

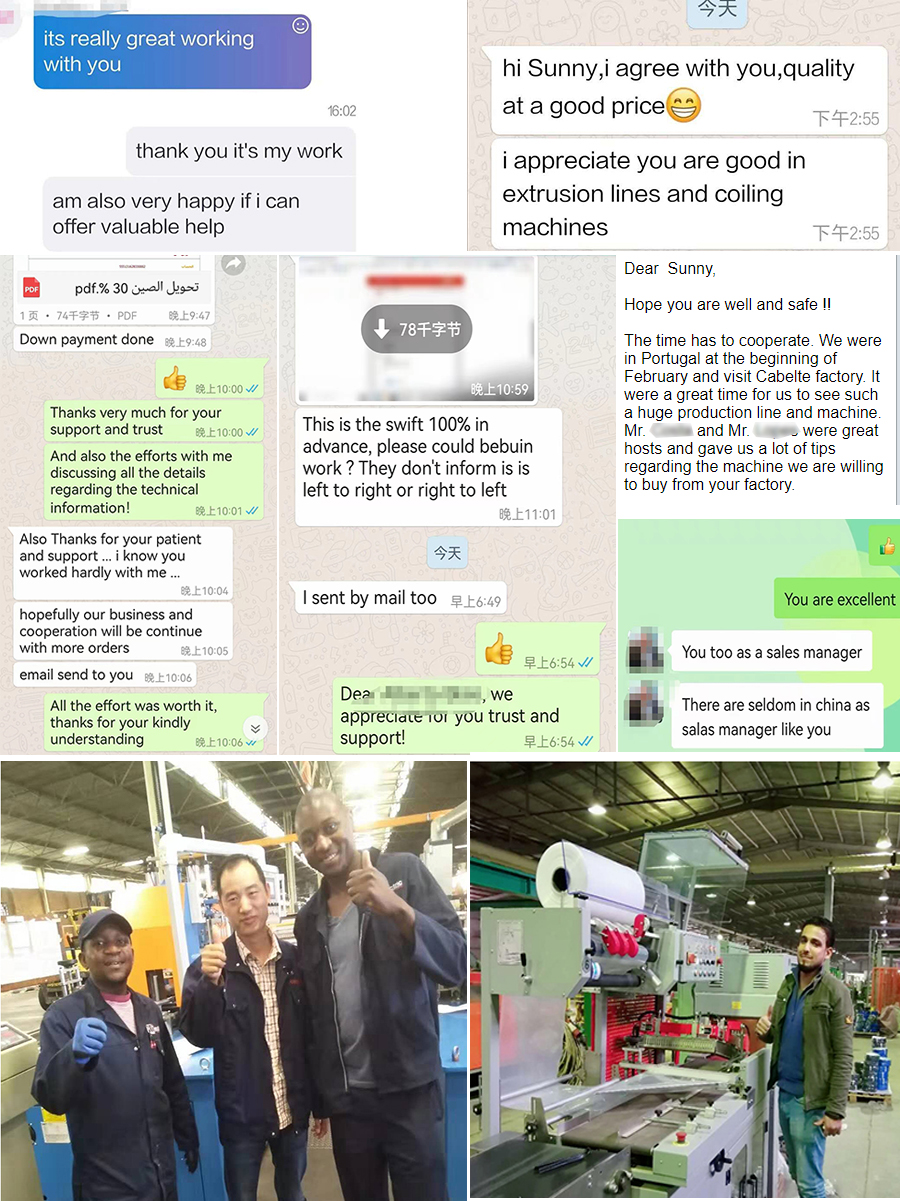

Customers' Feedback: