PRODUCTS

Create Value With Full Auto Manufacturing

- HOME

- PRODUCTS

- TURNKEY SOLUTIONS

- VIDEOS

- ABOUT HENGTAI

- NEWS

- MESSAGE

- CONTACT US

Copper Rod Continuous Casting and Rolling

The process for making copper rods using a CCR system includes:

Feeding copper cathode into the melting furnace

Casting the molten copper into a bar

Hot-rolling the bar into a rod

Cooling and chemically treating the rod

The raw materials used for a CCR system can be electrowon copper cathode or high-grade copper scrap. The resulting copper rods are usually of high grade and have a purity level of over 99.99%

The copper rod continuous casting and rolling (CCR) system uses shaft furnace for continuous melting and heat holding furnace for buffer and constant volume casting. The copper rod is hot-rolled and then surface treatment for cooling and reduction.

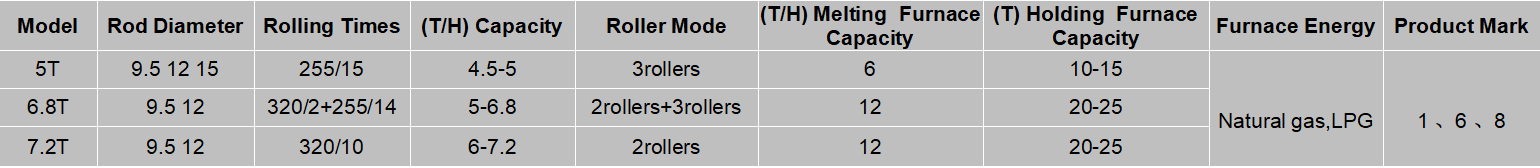

Technical Parameters:

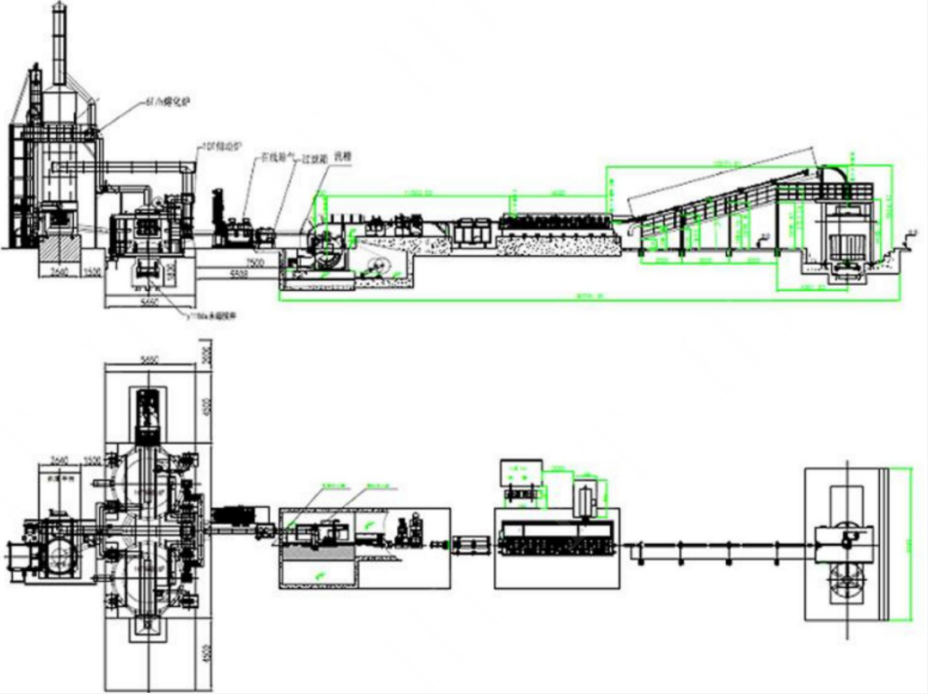

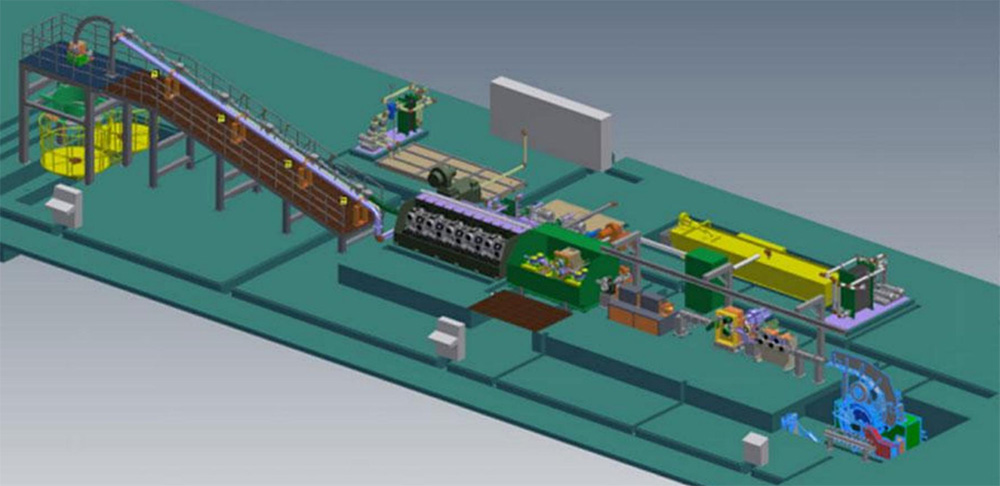

Layout of Production Line: