PRODUCTS

Create Value With Full Auto Manufacturing

- HOME

- PRODUCTS

- TURNKEY SOLUTIONS

- VIDEOS

- ABOUT HENGTAI

- NEWS

- MESSAGE

- CONTACT US

Aluminum/Alloy Rod Continuous Casting and Rolling Line

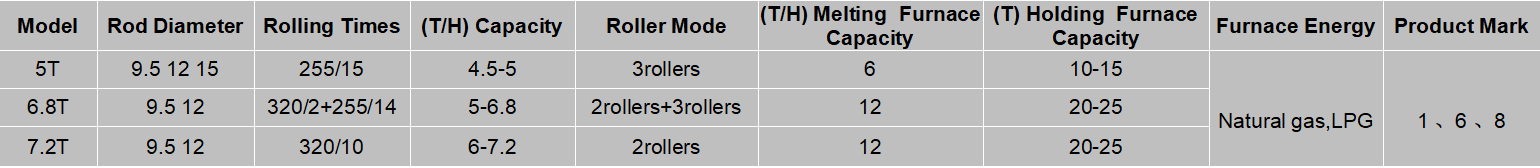

Aluminum continuous casting and rolling line works to produce pure aluminum, 3000 series, 6000 series, and 8000 series aluminum alloy rods in 9.5mm, 12mm, and 15mm diameters. The system is designed and supplied according to the processing material and related capacity.

1. The production line is mainly used in the high tensile conductive rod production of 9.5MM, 12.5MM, 15MM aluminum and aluminum alloy(EC1350, Series No 3#, 5#(5005、5154), 6#(6101/6201), and Series No. 8 (8176, 8030), etc. The technology of the line can meet the standard of European and American.

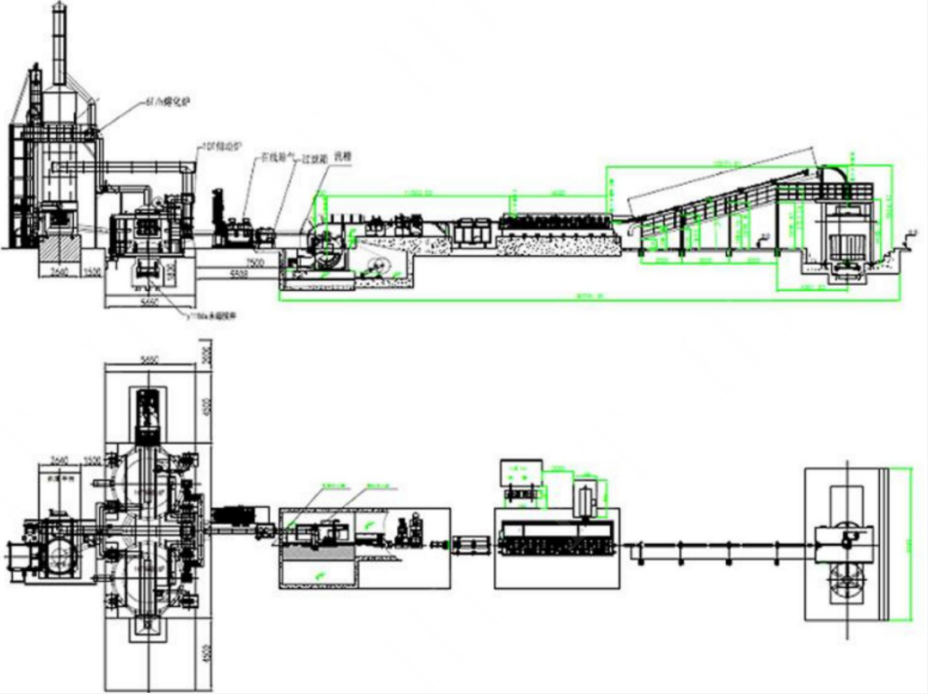

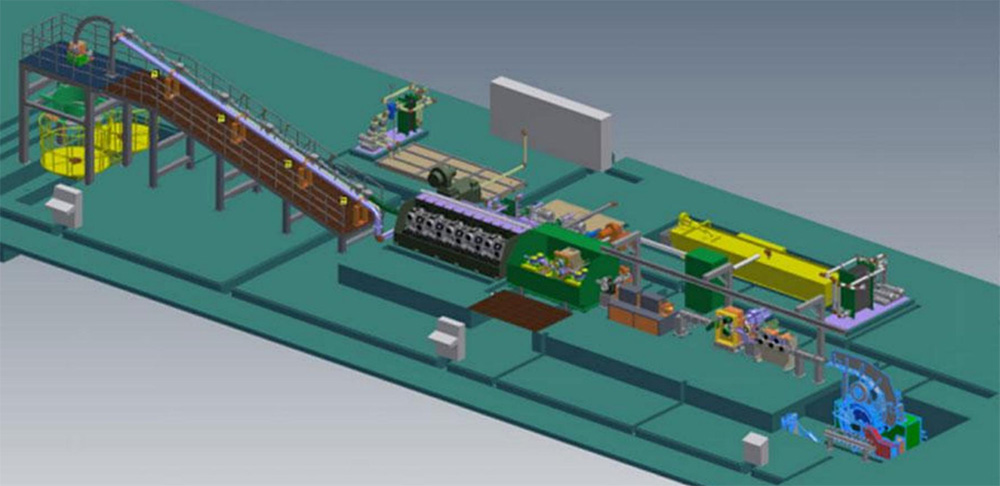

2. The production line is composed of the melting furnace, holding furnaces, four-wheel continuous casting machine, straightening machine, front traction, rolling shear machine, medium-frequency heating furnace, feeding machine, continuous mill machine, cooling system, take-up rod device, and electrical control system.

3. The crystallization wheel adopts an H-type structure, with all sides cooling and the ingot casting is dense and

uniform. There are three kinds of combination forms of two rollers type, three rollers type, and two rollers + three rollers type for customers. Provide the production line that output is 4.5 tons or 7.2 tons per hour.

4. The electrical control system design is advanced and adopts a programmable logic controller (PLC) +human-machine interface (touch screen) control, the electrical control system controls the whole line linkage and monitors the running status.

Technical Parameters:

Layout of Production Line: