PRODUCTS

Create Value With Full Auto Manufacturing

- HOME

- PRODUCTS

- TURNKEY SOLUTIONS

- VIDEOS

- ABOUT HENGTAI

- NEWS

- MESSAGE

- CONTACT US

Aluminum and Aluminum Alloy Melting Furnace

What are aluminum melting furnaces?

How they work

Aluminum melting furnaces use an induction coil to create a magnetic field. When an alternating current passes through the coil, the magnetic field changes direction at the same rate as the current's frequency. This induces eddy currents in the aluminum, which generate heat and cause the aluminum to melt.

What they're used for?

Aluminum melting furnaces are used in the recycling process and in the casting industry. They can also be used to melt other low melting point non-ferrous metals, such as copper, zinc, lead, tin, and cadmium.

Types of aluminum melting furnaces:

There are different types of aluminum melting furnaces, including induction and resistance furnaces.

Features:

Some aluminum melting furnaces have features like automatic temperature control, automatic melting, and a leak alarm device.

Machine Introduction:

1. The furnace mainly uses aluminum ingots, recovery materials, recycled materials, and others as raw materials. It can produce aluminum rods (1 series, 6 series, 8 series), aluminum ingots, aluminum bars and other products.

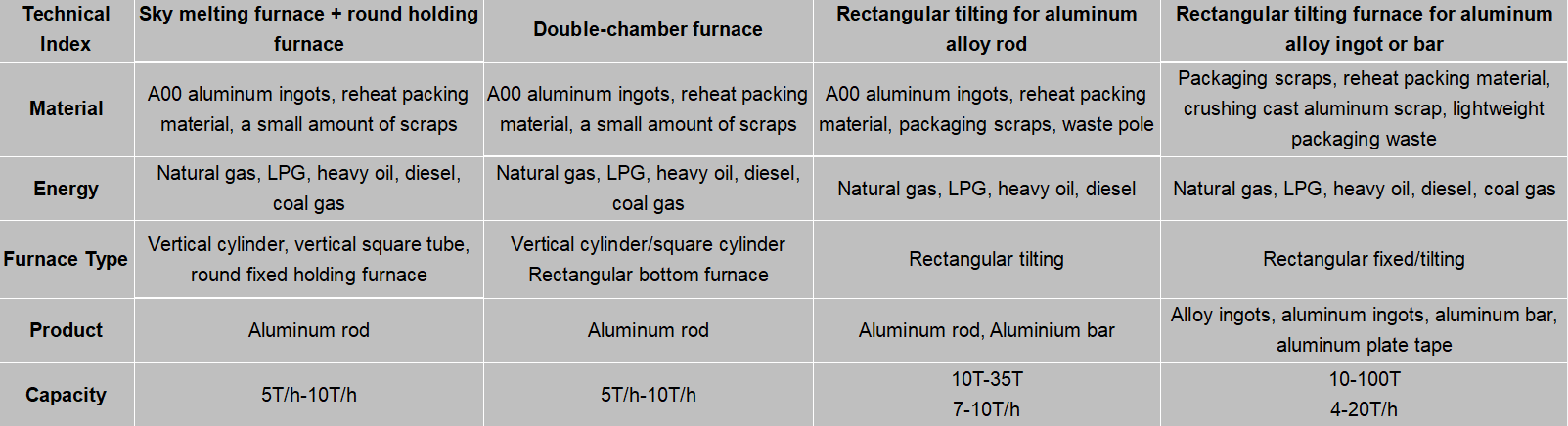

2. According to the customer requirements: sky melting furnace + round holding furnace (for melting), double-chamber melting furnace, rectangular tilting melting furnace, rectangular melting furnace for ingot or bar. Different furnaces have different applications and see the technical parameters table for details.

2. The furnace combustion system provides a variety of energy options.

3. The steel structure of the furnace was concerned with heavy-duty load during design. Refractory materials adopt a first-class brand to guarantee long service life.

4. The furnace adopts a regenerative combustion design and PID automatic temperature control. It has a higher thermal energy conversion rate, and it could save 20-40% more energy than traditional combustion systems.

5. Furnace adopts HMI+PLC control, centralized monitoring, and display. The technological parameters can be read and stored, and the touch screen can be modified directly. It is convenient and efficient.

6. It adopts a hydraulic drive furnace, laser measurement, and control technology, to ensure the stable flow control of casting aluminum liquid.

Application:

1. It can be equipped with two holding furnaces. Refining and slag-off will be completed alternately in the holding furnaces to ensure continuous casting of aluminum water liquid;

2. A rectangular furnace can be used for small-demand factories. Melting, refining, and slag-off will be completed in this furnace. Continue this process when it's empty.

3. It is equipped with an aluminum stirring system, online degassing system, and filtration system, which can be used to refine the composition of aluminum alloy and degassing and slag removal before casting;

4. It can be equipped with a continuous casting and rolling line to produce aluminum rods, a continuous ingot-casting machine to produce aluminum ingots, and a bar-casting machine to produce aluminum bars;

Technical Parameters: