PRODUCTS

Create Value With Full Auto Manufacturing

- HOME

- PRODUCTS

- TURNKEY SOLUTIONS

- VIDEOS

- ABOUT HENGTAI

- NEWS

- MESSAGE

- CONTACT US

Copper Rod Breakdown Machine

Copper rod breakdown is a process that uses a rod breakdown machine to draw copper wire from a copper rod

1. Used for drawing single or double copper rods for electrical purposes;

2. Produces φ1.2-4.0mm copper wires with φ8mm copper rods. And it is annealed

3. The mechanical speed is synchronized with the motor speed.

4. The dies can be replaced quickly and the bobbins can be unloaded automatically without stopping the machine.

5. An individual motor drives each drawing rim.

6. Each compression ratio can be set appropriately and conveniently for calculating die series.

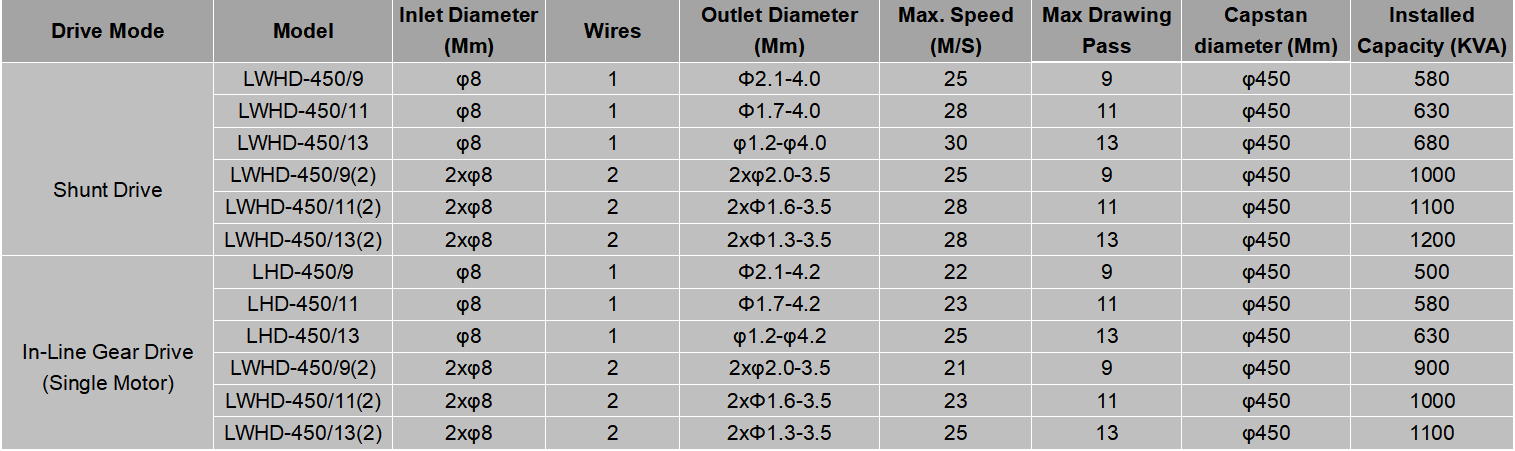

Technical Parameters:

Take-up form (optional):

1,630Single bobbin take-up ;

2,630Dual bobbin take-up ;

3,800Single bobbin take-up,

4,800Dual bobbin take-up ;

5,820Vertical pay-off;

6, Or above combination

Rod breakdown machines are a key part of cable plants, and they affect the quality of the cable, production speed, and electricity consumption. The process of drawing wire on a rod breakdown machine is the basis for producing all kinds of wires, strands, and conductors.

Here are some features of rod breakdown machines:

Dies and capstans: The dies and capstans are submerged in coolant to prevent overheating, wire oxidation, and surface problems.

Annealing shafts: The annealing shafts are internally water-cooled.

Slip: The machine can have a slip that works with the real wire speed in each capstan.

Horizontal structure: The machine can have a horizontal structure and dual driving motors.

Rapid die change system: The machine can have a rapid die change system.

High-precision gear transmission: The machine can have high-precision gear transmission.